The Demand for NVIS-Compliant Illumination

There has been an increasing demand for products capable of NVIS-compliant illumination and other standard avionics chromaticities defined in MIL-P-7788, which has resulted in a common practice of integrating dual-mode NVIS illumination into instruments.

Design engineers of illuminated avionics panels and display instruments continuously seek to increase performance and reduce material and manufacturing costs. At the same time, customers of some military products are attempting to standardize products to benefit from larger procurement volumes. In general, and given the standard applications’ volume from a few hundred to low thousands per year, the unit price remains significantly sensitive to volume, with manufacturing cost stabilizing only at much higher quantity breaks. As a result, these customers now require certain products to be capable of NVIS-compliant illumination and other standard avionics chromaticities defined in MIL-P-7788. This enables the larger purchases of standardized products, which become customized only in the application.

As the leading provider of night vision materials, Cevians offers a variety of solutions for such requirements. We will present solutions in this article and provide an overview of common assembly errors.

MIL-P-7788 Compliant Solutions

A common industry practice is integrating two independent backlight systems into the design of display products based on their requirements for various mission types – day or night. In these typical arrangements, several white LEDs will provide AMLCD backlight energy during day mode operations, and a set of night mode LEDs will be activated during night missions. To accommodate the filtering required of these night mode LEDs, Cevians presents several solutions, including Cevians SafeNight polymers or thin-film coated glass with BlackBackground technologies. As a result, the display assemblies will include a combination of standard white LEDs and filtered white LEDs, of which the near-infrared light is attenuated to provide Night Vision compatibility.

Similarly, in compliance with MIL-P-7788, some illuminated panels have been required to provide different illumination chromaticities depending on the end product utilization. This often includes the ability of the product to emit blue-filtered white, IPL white, and NVIS green A or B-compliant light. Again, this is achieved by integrating independent light-emitting diodes, some being standard white LEDs. In contrast, others would include Cevians NVISable LEDs to satisfy the green A or green B requirements.

Risks and Considerations

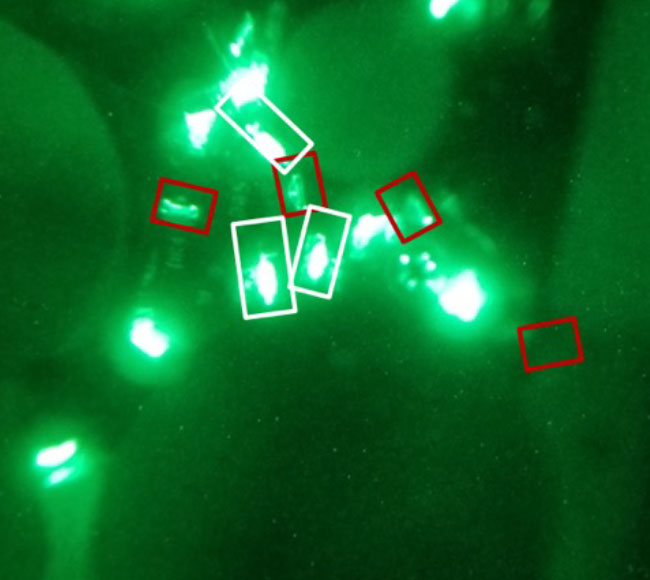

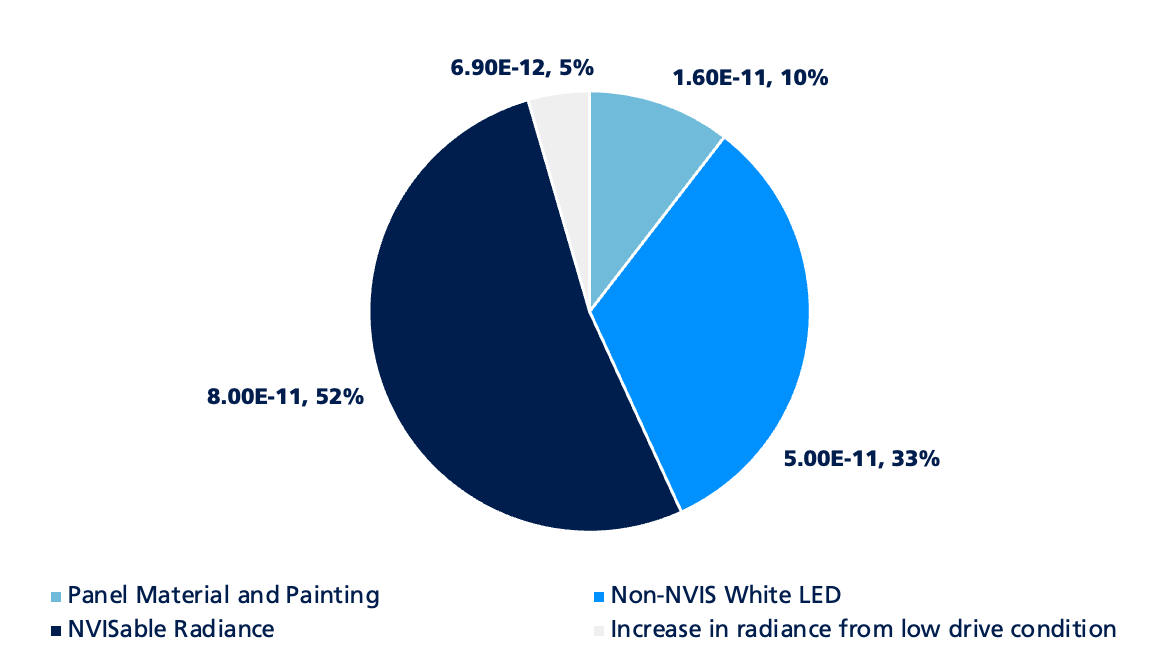

In the design process, there are crucial elements to consider when ensuring illuminated panels comply with radiance compliance, particularly critical with dual-mode product designs. Despite using fully compliant NVISable LEDs, illuminated panels can still fail compliance tests when additional radiance is not accounted for.

In these designs, the engineers must closely consider the materials’ nature in the assembly. Many materials will have fluorescence characteristics and, as a result, will absorb light energy at specific higher frequencies. A portion of this energy might be re-emitted at lower frequencies in a process known as Stokes shift. It is important to remember that the energy re-emitted at lower frequencies is re-emitted at higher wavelengths as they are inversely related, fλ = c. In most cases, the energy level is insufficient to impact the desired design objectives related to chromaticity. It is, however, essential to consider that the re-emitted energy might be in the range of sensitivity of the night vision goggles and that it could be sufficient to impact the radiance of the total light emission.

This fluorescence is critical and significant in these dual-mode product designs as it integrates several white LEDs for either day-mode operations or non-NVIS illuminated panel chromaticities. This is critical because the white LEDs are essentially fluorescing components. At the core of the white LED is a blue light-emitting diode that is then encapsulated by the most common YAG phosphor doped with cerium (CE:YAG). In day mode, the blue LED die is energized, and a portion of the blue energy is absorbed and re-emitted at higher wavelengths, including near-infrared in the night vision goggles sensitive region. Of no significance during the day, this phosphor is equally stimulated by energy emitted by NVISable LEDs during night operation. The NVISable LEDs emit essentially no detrimental near-infrared energy. It does, however, provide significant visible energy absorbed by the non-power day LED phosphor, which then re-emits energy in the near-infrared, affecting the overall radiance of the illuminated panel.

The re-emitted energy is a function of the level of stimulation, and consequently, the designers should carefully consider the product’s optical geometries and LED locations to minimize secondary fluorescence. Failing to consider this additional radiance contribution risks the illuminated panel failing radiance compliance despite using fully compliant NVISable LEDs.

The demand for products capable of NVIS-compliant illumination and other chromaticities, as defined by MIL-P-7788, is increasing. Designers continually seek solutions to meet these requirements while reducing material and manufacturing costs. When properly constructed and measures are taken to reduce assembly errors, Cevian’s NVIS Products is an ideal solution.

View Cevians products referenced in this article here: