Ultimate Performance

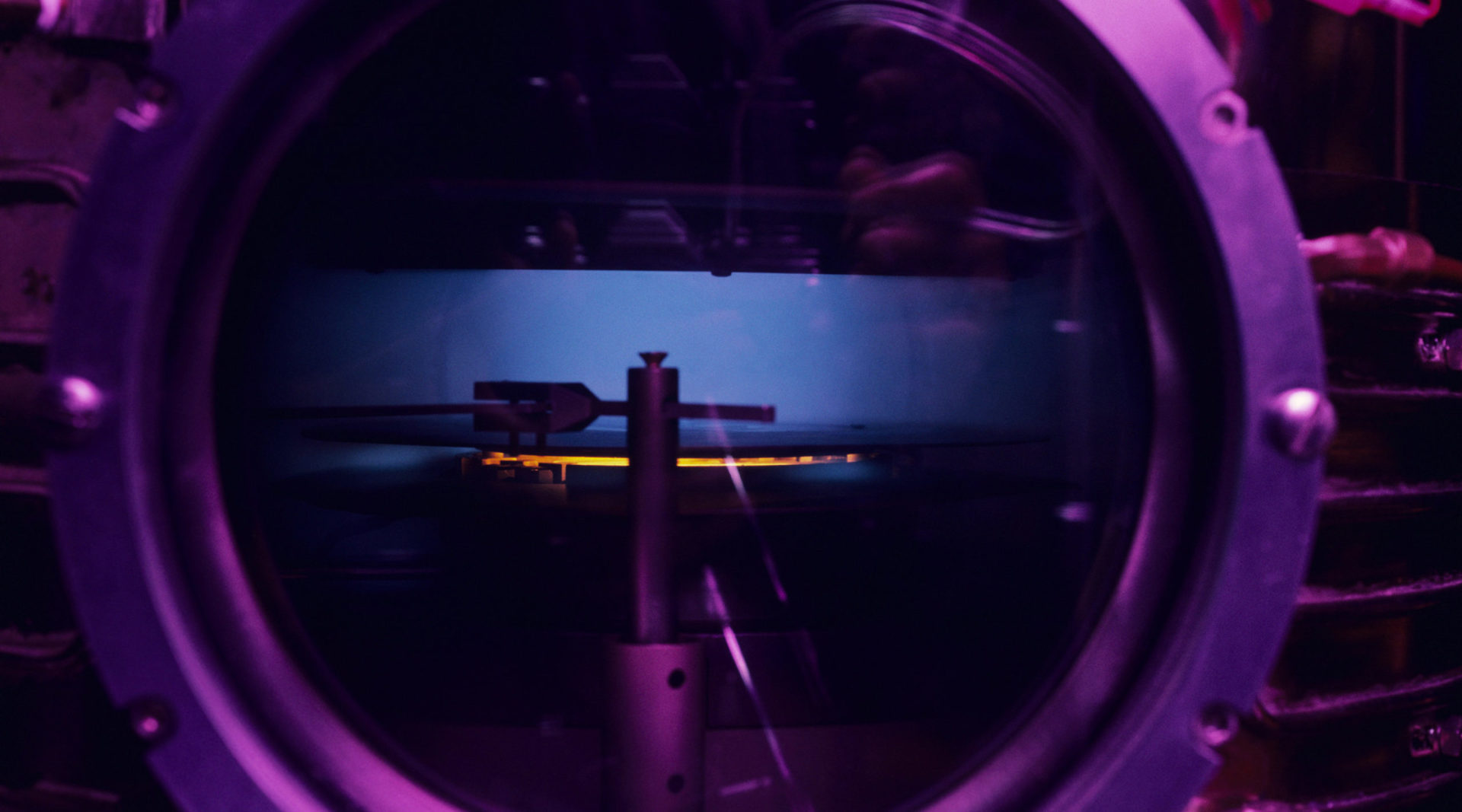

We specialize in high-performance thin-film coatings for complex applications. Our custom high-count optical layers coating are designed and manufactured with unparalleled precision using unique coating chambers and advance optical monitoring system.

Highly Optimized

By leveraging the advantages of our bespoke coating technologies and equipment, Cevians can optimize thin-film coating strategy for highly specific requirements. This includes Plasma Enhanced Magnetron Sputtering, Ion assisted Evaporation, and large-area automated equipment optical measuring. We support small to large volume production and perform optical, mechanical, and environmental qualifications in-house.

Over 25 Years in Aerospace

With over 25 years of high-performance optical filters in aerospace applications, Cevians products have been in service in the most demanding applications including UH-60, F-35, B-52, Eurofighter, F-15, F-16, AH-64 Stryker, MRAP, and numerous others.

Technical Summary

- Sputtering and Evaporation deposition platforms

- Plasma enhanced processes ensure dense, low loss films

- In-situ optical monitoring provides extremely tight layer thickness accuracy and repeatability

- Design and coating capabilities over 0.3 – 20 micron wavelength range

- Custom filter design per customer specification

- Filter types including bandpass, long wave pass, short wave pass, multi-band pass, notch, dark mirrors, cold mirrors, hot mirrors, anti-reflection, high reflectors, beam splitters, and ITO and index-matched ITO

- Low loss coatings with passband transmission up to 99%

- Blocking up to OD 6 across the silicon and InGaAs detector ranges and up to OD 7 across narrower ranges.

- Edge uniformity of +/- 0.5% over large-format optics

- Bandpass FWHM as narrow as 1-2% of CWL

- Low sensitivity to angles of incidence (AOI)

- Large format substrates up to 452 square inches.

- Substrate materials include borosilicate glass, filter glasses, fused silica, sapphire, and IR materials

- Low-temperature processes compatible with polymer substrate materials

- Uniform coatings on both flat and curved substrates

- Environmental stability with no humidity or temperature shift

- Durability performance exceeding MIL-C-48497A

- Environmental performance exceeding MIL-STD-810F & MIL-STD-883

- Filter performance stable across temperature range -55°C to 150°C and thermal shock

Industry-Leading Deposition Technologies

Custom-Designed Filters

Broad Range of Substrate Compatibility

Robust Environmental Characteristics:

Custom Thin-Film

Neutral Density

- AVG Trans. 5 to 95%

- tolerance+- 2%

Hot Mirror

- cut off (50% wl) up to 1000 nm

- tolerance +- 1% of 50%wl

Cold Mirror

- Turn on (50% wl) up to 1000 nm

- tolerance +- 1% of 50%wl

Band pass (Single and Multiple)

- Center WavelengtH (CW) per customer spec

- FWHM 0.5% of CW

Anti-Reflective AR

- AOI 0 to 45 deg

- Photopic reflectance < 0.3

- Neutral Density Filter

- Hot Mirror

- Cold Mirror

- Multi-Band Pass

- Single Band Pass

- Visible AR