The Custom LCD Display: An Essential Tool for Military Operations

The custom LCD display is essential in military operations, enabling teams to view critical information, such as maps, navigation, and tactical communications. In addition, custom LCDs are integrated into avionic and ground vehicle vision and sensor systems to provide real-time information to pilots and drivers. Due to the harsh environments and demanding applications, it is often necessary to customize military LCDs to withstand extreme conditions, such as wide temperature ranges, high electromagnetic susceptibility, and viewing environments.

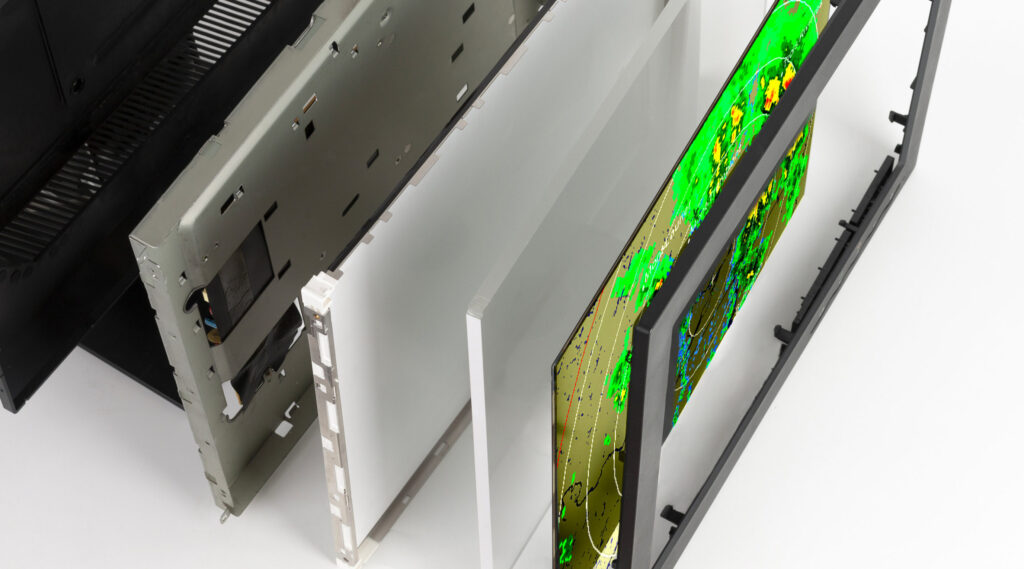

A COTS Display Vs. A Custom LCD Display

There are several key differences between COTS (Commercial Off-The-Shelf) Displays and custom displays. Although COTS displays are generally cheaper, more readily available, and faster to implement, customization options for challenging military applications are limited. Alternatively, custom displays initially are higher cost but offer many benefits as opposed to COTS, including the ability to tailor features precisely, stricter quality control measures, a longer lifecycle, and the ability to meet the parameters of military qualification testing.

In the demanding context of military operations, where equipment’s durability and reliability are absolutely essential, optical components and enhancements are needed to ensure that the LCD’s liquid crystals, electronics, and touch sensor elements function properly. Because of the extreme and unpredictable environment in which operations occur, custom LCD displays are needed. Customizations such as sunlight readability, night vision compatibility, shock and vibration resistance, and other specific ruggedization features must be implemented.

Designing custom LCDs for military applications requires balancing cost, performance, and expertise to select components and integration methods to meet the highest performance and reliability standards while managing costs.

Balancing Budget and Performance

While costs vary depending on the individual needs of the custom order, ruggedized custom LCDs will generally incur extra costs due to the specialized manufacturing techniques required to add the features.

From a Size, Weight, Power, & Cost (SWaP-C) perspective, custom displays can be designed to meet specific applications such as vehicles, avionics, or mobile computing applications. Customization is often required to address the challenges of using higher resolution displays that draw more current, generate more heat, and may produce more radiated emissions. To improve EMI/RFI compatibility and operation over a wide thermal range (-40 to + 85 deg. C.), performance is addressed by:

- Integrated optical components – Antireflective (AR) and low resistance conductive coatings/grids applied to display cover glass, PCAP or resistive touch screen sensors

- Transparent heating elements – Flexible and rigid substrates with transparent conductive coatings, parallel busbars, and wire attachments to create a resistive heating element when current is applied. Power density range 0.5 to 5 watts/sq.in.

- NIR/IR Coatings – thin film absorptive or infrared reflective coatings integrated into the cover glass or lighting systems for passive thermal control, NVIS compatibility

- Ruggedization – impact, shock/vibration resistant components optically bonded to optical system to meet parameters of 810F environmental tests, moisture ingress

- Lower Power Components– for mobile electronics, ability to operate with low power consumption to conserve battery longevity and control EMI/RFI, thermal emissions

Substrate selection, optical coating design, and integration techniques enable multifunctional performance enhancement and cost control. For instance, conductive coatings can be used to simultaneously address NIR, EMI/RFI, and transparent heating applications.

There are several ways that the DoD manages costs associated with military equipment while still ensuring that the equipment meets the requirements, including assessing long-term expenses such as maintenance, repairs, and upgrades. The equipment lifecycle is closely tracked, which helps define a clear plan for when technology insertions, upgrades, and replacements are required. Additionally, upgrades and repairs are tracked separately to ensure spending accuracy.

Critical Performance Standards for Military LCDs

There are several key performance metrics that displays must meet in demanding military environments per MIL-STD-810, including resistance to extreme temperatures, dust, moisture, vibration, and shock. A custom LCD display is designed with high luminance to enable readability in direct sunlight. Resistance to electromagnetic interference (EMI) is also critical, as it ensures the display will remain functional in environments with high electromagnetic fields and produce low radiated emissions.

Cost Management and Lifecycle Planning in Military Equipment

Commercial displays not specifically designed to withstand harsh environmental conditions may result in failures in display performance, leading to expensive replacements and delays in critical operations. Reliability and precision are not negotiable in these demanding environments, as they must deliver real-time, mission-critical information seamlessly.

Market Demand in the Military Sector

The market for military displays is rising and is expected to reach a market value of $1.89 billion by 2033. The military’s increasing adoption of emerging technologies such as AR and VR will drive further growth in the next few years.

LCDs accounted for 36.7% of the military display sector in 2023, making up the largest segment. Moving forward, AMOLEDs are projected to be the fastest growing industry segment and airborne applications for military displays. (GlobalNewsWire)

Other rising trends include an emphasis on microdisplays, wearable military displays to enhance situational awareness, and the development of a smaller, lighter, and more accessible HUD (head-up display). Military procurement processes shape demand by defining requirements, setting budgets, and enforcing strict compliance standards. These processes drive innovation as defense contractors invest in R&D to meet military needs, often influencing commercial markets.

Cevians: Ensuring Reliability and Performance in the Military LCD Display

Cevians addresses key challenges in military LCD displays through our expertise and vertical integration in designing, manufacturing, and integrating optical components such EMI and NVIS filters, heater glass, NVIS LED’s, and custom touch screen to enhance LCD durability, visibility, and compliance with strict defense standards. With over 50 years of experience developing custom solutions, our displays adhere to MIL-STD-810, MIL-STD-3009, and MIL-STD 461 specifications outlined for ground and airborne applications and are manufactured in the US with the highest performance standards.